Flat or Cupped

The preferred choice for workpieces with a flat or slightly curved surface, providing great stability due to their flat shape. The flat shape makes them suitable for use on many materials including glass, metal, and cardboard. They are also suitable for handling heavy metal objects.

Bellows

Bellow suction cups are typically used for workpieces with uneven surfaces or varying heights. These suction cups are often used for the handling of fragile workpieces, packaging, and injection molded parts, etc.

Suction cups with multiple bellows are considered suitable for handling food packaging and shrink-wrapped products.

The shape of these cups permits them to collapse when in contact with the surface of the load and while in the presence of vacuum. They can be used in applications where the load may have an irregular surface (not completely flat, as described above) or for gripping on inclined surfaces. They also provide a lifting movement which helps to separate thin materials. They are NOT suitable for the vertical handling of heavy loads.

Most commonly come without cleats.

Oval

Oval vacuum cups are ideal when handling narrow and elongated work pieces. They are available in either flat or bellows.

Due to their high coefficient of friction, these cups are often used in the handling of oiled sheets, marble, and wet glass, as well as loads subject to high acceleration and deceleration, and when a maximum holding force is required.

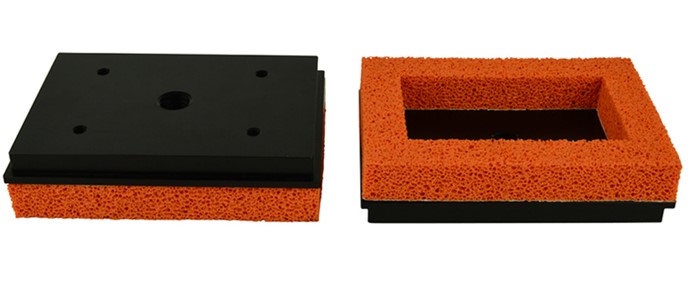

Foam

Foam vacuum cups are great for handling rough and textured surfaces.

What details are required to properly spec in a suction cup?

- the weight and dimensions of the load

- the speed and direction of the load (horizonal to horizontal, horizontal to vertical, rotating 90⁰ on the horizontal plane, etc.)

- surface texture of the load

- temperature of the load to be lifted

- presence of oils, solvents, chemicals, etc.

- work environment: indoors or outdoors, subject to radical temperature swings, presence of high or low temperatures

- what is the product being handled? Is it food?

- will your application permit the cup to leave a mark or print on the load?

- do electrostatic charges need to be dissipated from the gripping surface?

- what industry is the cup being used in?

Some of the More Common Materials Suction Cups Are Made Of

NBR, also known as Nitrile Rubber or Buna-N – excellent resistance to wear, ageing, chlorine-containing oils, grease, and petroleum. It also offers low permanent deformation and does not leave marks on the gripping surface.

NBR cups are often used in general industrial applications and is most certainly found in steel handling, plastics handling, and any other applications where the cup needs to be resistant to oils and related chemicals. In most applications, this is the “go-to” material based on its lower cost, availability, and good wear resistance.

Natural Rubber (NR) – great elastic yield and resistant to wear, cutting, and tearing. Great elongation at break. These cups, however, offer poor resistance to ageing, oils, and heat. Non-toxic natural rubber vacuum cups are available.

Their highly flexible nature allows these cups to grip on very rough and irregular surfaces. Common applications include gripping paper, carboard, plastic, and plastic film for the packaging industry.

Nitrile Rubber (NBR) – resistant to oil, heat, and ageing, as well as permanent deformation. These cups are great in heavy-duty environments. Suitable for gripping metal plates, glass, and loads with a smooth surface.

Silicone – the greatest advantage for these cups is their extreme temperature resistance – both hot and cold. They are ideal for handling frozen packaged food and hot plastic-injected molded parts with a temperature range more than 450ºF (230ºC). Silicone is also offered with FDA compliance to allow for direct contact with food and pharmaceutical products.

Anti-Static Silicone (VMQ-AS) – great for use at high and low temperatures. Highly conductive & anti-static. They can, however, leave marks on the gripping surface. These cups are not recommended for food use. These cups are often used in the electronics industry, the recording industry, and myriad other applications where electrostatic charges need to be dissipated from the gripping surface.

Polyurethane – used in potentially high-wear applications. These cups have a very high wear resistance when compared with both silicone and NBR. They are, however, typically more costly.

Their temperature-resistance range is less than both NBR and silicone.

Vinyl or PVC (Polyvinyl Chloride) – relatively low-cost alternative to the materials mentioned above. These cups typically have a limited range as far as temperature and durometer (hardness) is concerned.

Looking for more information? Please send us a note through our Contact Us page. We’d be happy to answer any of your questions.