When considering the brand and style of automatic tool changers you’re going to want to consider a few factors, not the least of which is the style of the coupling mechanism. Your choice is commonly between Cam & Dowel vs. Ball & Collet.

Cam & dowel systems offer several distinct advantages, including:

- Wear compensation – cam and dowel systems “wear in” instead of out, maintaining like new performance throughout the lifetime of the tool changer

- Lowest cost of maintenance – Maintenance is performed simply by checking the bushings, locating pins and if needed, greasing the cams.

- Maintenance – Effecto offers a lifetime guarantee on the coupling mechanism parts for their line of Epsilon tool changers

- Ease of integration – direct bolt design to limit the need for adapter plates

- Suitable for harsh environments

- Self-Cleaning

- Positive cam retraction – air is required for both couple and decouple. When ball & collet systems are exposed to dirtier environments the potential exists for the balls to become jammed in the collet, prohibiting proper and safe release.

- Safety (to both personnel and equipment) – when a guide pin breaks on a ball & collet system the end-of-arm tooling can “free-wheel”. This is not a concern with Epsilon XCHANGE cam & dowel tool changers.

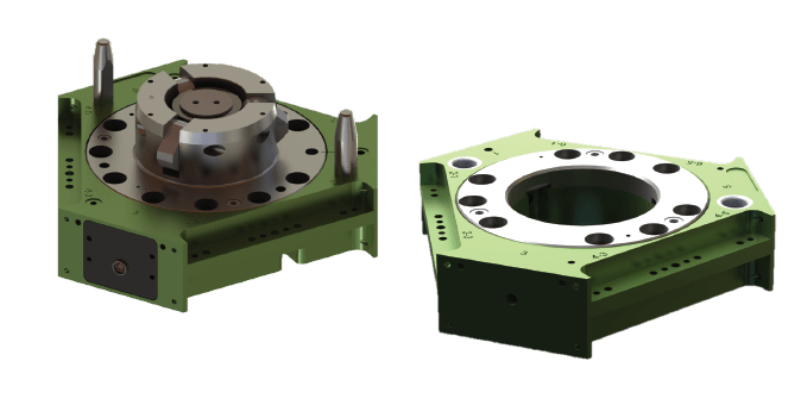

A few other things to consider when it comes to the Epsilon XCHANGE line of tool changers:

- have a high strength aluminum alloy body

- Are self-centering

- Optional couple/uncouple sensing is available upon request

- Can pass thru electrical wires, fluid (coolant), as well as pneumatic air lines

- Can incorporate all pneumatic, hydraulic, electric, and electronic coupling modules & components

- Effecto offers a lifetime guarantee on the coupling mechanism parts for their Epsilon line of tool changers