We are pleased to support and promote the Weiss line of Rotary Indexing Tables.

What is a Rotary Indexing Table?

A rotary indexing table is a mechanical device used in manufacturing & automation processes to precisely position and rotate workpieces or tools at fixed intervals. It plays a crucial role in applications requiring accurate and repeatable positioning.

Commonly used terms for Rotary Indexing Tables include:

- Rotary Indexer

- Rotary Table

- Rotary Positioning Table

- Automated Indexing Table

- Industrial Rotary Table

The Weiss line of Rotary Indexing Tables includes cam indexers, servo-mechanical indexers, and direct drive units.

Indexing tables (excluding controls) typically ship from the Weiss Willoughby Ohio warehouse within 4 weeks from the date of order.

Weiss offers the best warranty in the industry: 4-year mechanical, and a 1-year electrical.

Ease of Ownership: you DO NOT need an overload clutch with the Weiss line of Rotary Indexing Tables. Furthermore, Weiss indexers are virtually maintenance free, as you NEVER need to change the oil.

Fixed-Station Indexers (TC and TR)

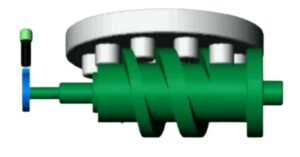

Fixed-Station indexers are driven by a high-precision cylinder cam. The movement pattern is determined by the cam track. The cam takes the constant motion of the motor and transfers it to the dial plate.

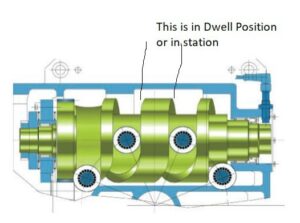

The number of stations is determined by the dwell (flat spot on the cam).

- TC indexers offer 2 to 60 positions.

- TR indexers offer 4 to 36 positions.

These units are extremely accurate and offer zero backlash due to the tensioned cam-followers at the stop positions.

Other notable features include:

- Smooth motion profile

- Low maintenance: no oil changes are required and the use of a VFD eliminates brake wear

- Highly accurate & repeatable

- Proximity switch indicates when the unit is in-station

- Sturdy cast iron housing

- Triple bearing of the rotary plates to ensure high loads

- Brake energized to release

- Load tested prior to shipping to make certain the indexer meets your speed and cycle-time requirements

- Mechanics are stronger than motor power: you cannot break the cam followers. This is primarily why Weiss rotary indexing tables do not require an overload clutch. With the Weiss line of indexers, you cannot exceed the permitted inertia.

- Compact Design: no external gear box or overload clutch

- Multiple drive positions available

- Multiple mounting positions available

- Stationary centre with through hole

- Side window for cabling

- Special voltage options are available

- Systems come with a PNP prox switch as standard. NPN are available upon request.

- Stationary plate – can mound additional components. All surfaces from the casting to the rotating dial plate to the stationary plate have accurate mounting holes/dowel holes. All the customer needs to do is transfer the bolt hole and dowel hole pattern to their mounting plate.

- Motor and pulley housing have a smaller profile than the casting itself, saving the customer the need for costly cut-outs in the machine top plate.

- Clean room modifications are available upon request – EN plating on dial & stationary plates, Steel-It epoxy paint, sealed belt housing, & stainless-steel exposed fasteners

TR Fixed-Position Rotary Indexing Tables

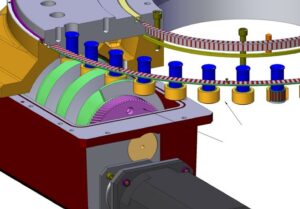

Within the line of Fixed-Station Indexers is the TR line of products. TR indexers provide a sizeable centre hole to permit equipment to be placed at the centre of the indexer. Think of it as building your system from the inside out.

Key features of the TR line if indexers include:

- Same robust design as the TC line of indexers

- Large open centre to permit larger equipment to be mounted at in the centre of the unit

- Same robust design as the line of TC indexers: 4-year mechanical warranty, low maintenance, no overload clutch

- Dial plate comes with a standard mounting pattern to attach a tool plate (2 dowel and 6-8 tapped holes).

- Stationary plate come with 2 dowel holes and 2 to 10 tapped holes.

- Low profile (raised supports available)

- Cam followers run along the entire outside perimeter of the track offering greater levels of accuracy

Controls

VFD

- Most common option

- Requires the customer PLC to run the indexing logic

- Can adapt supply voltages/frequencies to work with a standard motor

- Eliminates the need for motor brake during normal operation

- Weiss can supply a Rockwell PowerFlex 525 drive, with all parameters set by Weiss North America. Weiss would then include a parameter sheet with the settings. Braking resistors are also available if needed.

TS Control Card

- Simple Interface that handles the indexing logic

- Requires either motor contactor or VFD for motor power

- Requires an index start input (from the customer’s PLC, safety interlock switch, etc.)

Fixed-Station Rotary Indexing Tables come with a fixed number of stop positions. Once the equipment has been manufactured the number of stops cannot be altered. If you’d prefer the ability to change the number of stop positions later, you’d be better served selecting Freely Programmable Indexers (NC, NR, CR).

Freely Programmable Indexers (NC, NR, CR)

Think of these as freely programmable versions of TC and TR indexers.

- Constant lead cams: doesn’t have a dwell machined into the system like the Weiss line of TC and TR indexers. Positioning is determined by servo motors (typically).

- No “in-station” prox switch

- Optional secondary encoder for NC. Weiss can supply the encoder or prep mount a customer supplied encoder.

CR Indexers (Heavy-Duty)

- High load & forces

- Constant lead cam (servo driven, freely programmable)

- Great for automotive welding applications

- Larger number of cam-followers are engaged (can carry more inertia)

- Increased inertia

- High Output Torque – always have 5 cam followers engaged in the cam

- Quick index times

- Quick e-stop times (great for light curtain applications)

- Multiple motor options: Weiss control package, Weiss supplied Rockwell motor, customer supplied motor

Direct Drive & Hybrid Indexers (TO, ST, TW)

TO – Torque Rotary Table

- Freely programmable

- Direct, rigid connection of the load to the drive

- High speed

- User programs the direction of rotation

- All motors equipped with temperature protection

- Lubricated for life

- Highly accurate and repeatable

- Long service life

- Low maintenance

ST – Torque Rotary Table

- Freely programmable

- Small & compact

- Lightweight

- Any installation orientation possible

- Commonly put on the end of a tool

- When fast, precise, and highly dynamic rotating, tilting, and gripping motions are required

- Great for feeding or orienting parts

- Swivel module for grippers

- Commonly replace standard servo motors with planetary gears

- No oil, no gears

- High power density

- Optional holding brakes

TW – Hybrid Drive Rotary Table

- Freely programmable

- Designed to greatly outperform pneumatic indexing solutions

- Comparable in cost to pneumatic solutions

- Higher power density than pneumatic solutions

- Hybrid drive includes gear reduction

- Servo and gear are built inside the unit

- Permits any installation orientation

- Integrated servo motor with holding brake

- Absolute encoder

- Precise teaching of each position

- Electronic overload protection

- Direct drive motor – faster & more precise than pneumatic solutions, very little dwell time

What We Need to Know in Order to Quote a Rotary Indexing Table

There are a few basic details we need to have in hand to provide a quote. They are:

- Fixed-position or freely programmable?

- Tool plate diameter

- Tool plate thickness

- Tool plate material

- Number of stations

- Number of holes in the tool plate per station

- Weight per station (part + fixture)

- Radius – distance from the centre of the indexer to the centre of gravity for the nests

- Target indexing time

- Dwell time (time in station)

- Motor operation (continuous or cycle-on demand)

- Rotation directions (clockwise, counterclockwise, reciprocating)

- Supply voltage, # of phases, and frequency

- Brief description of the application

- Additional requirements

We’d love to hear from you. Please feel free to send quote requests via our Contact Us page by clicking here.

If you have an application that you require help with and would prefer an in-person consultation that is something we’d be delighted to do as well. Please simply send us a few pertinent details, as well the location of your facility.

We respond to all inquiries made via our website inside of 24 hours.