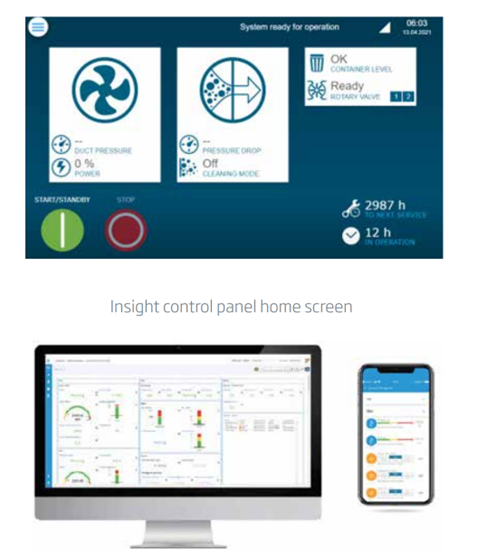

Filter technology has come a long way. Case in point: Nederman’s MCP SmartFilter. This filter offers a dust collection control panel that includes and easy-to-use HMI and IoT gateway, allowing the system to be cloud connected and remotely monitored.

Nederman – MCP Smart Filter

Insight control HMI – a cloud-based IIoT platform that provides real time monitoring, visualization and tracking of system performance, including customized dashboards, alarms, and reports. Real-time data is accessible via the web with the data being stored in the cloud to permit further and subsequent analysis.

There are several important filter parameters that need to be monitored to ensure your system is performing adequately. They include:

- Filter Pressure – monitoring filter differential pressure (dP) helps evaluate filter life and filter cleaning effectiveness. High filter pressure translates into increased energy use and higher emissions resulting from increased cleaning cycles.

- Duct Pressure – sufficient airflow is a paramount concern when using a dust collection system looking to protect people and equipment from airborne contaminants. Measuring the duct or hood pressure is a useful way to determine if the system is working optimally.

- Compressed Air Pressure – when the cleaning pressure is too low the filter may not be cleaned properly, resulting in reduced airflow, shortened filter life, increased energy consumption and higher operational emissions from increased cleaning frequency, not to mention added wear and tear on the filter itself. Conversely, pressure that is too high risks damaging the filters, increasing noise levels and requiring more energy consumption.

- Dust bin level – It is important that the dust bin is not allowed to overflow. Being able to monitor the level of the dust in the bin helps save time, avoids the unnecessary emptying of the bin when it is not full, and helps avoid bin overflows.

- Fan performance -The fan consumes the majority of energy required to operate the system, so ensuring that the motor is operating properly is important. Excessive vibration may cause the fan to fail, or at the very least dramatically shorten motor life. Avoiding these scenarios helps save money spent on costly overtime and unplanned outages.

The Nederman IntelliPULSE cleaning module maintains a constant differential pressure drop across the filter element while reducing the amount of compressed air being used. This results in:

• Lower Operating Emissions – from less filter pulse cleaning cycles.

• Reduced Energy Consumption – Decrease compressed air and energy requirements by up to 40% over set-point adjustment and 90% over continuous cleaning.

• Maintain Airflow – maintaining a consistent and low pressure drop helps to regulate airflow & as well as the corresponding transport velocity

There are several other features and benefits yet to cover, but this gives you a good start to understanding what’s available to you. Naturally, each application is different, so please feel free to reach out to us with your specific requirements. We’re here to help. You can send us your specific application details by visiting our Contact Us page.