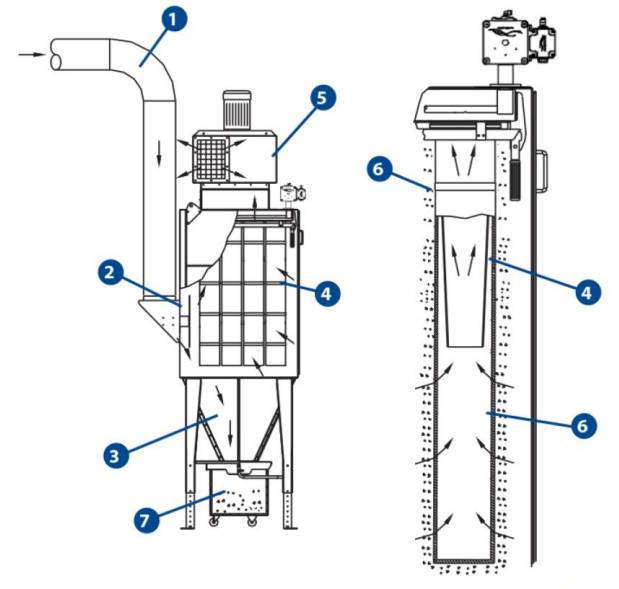

During Normal Operation

- During normal operation, the dust laden air from the plant travels down the supply duct

- A baffle (2) mounted at the inlet of the filter breaks up the airflow and directs the dust downward into the hopper (3). This helps to protect the filter cartridges from the abrasive dust.

- The lighter dust collects on the outside of the Squircle filter cartridges (4), with clean air passing through to the to the inside of each cartridge. The clean air then travels through the air handling fan (5) to be returned to the plant or exhausted outside.

- The heavy dust collected into the hopper is discharged into the metal bin (7), 55-gallon drum, or through a rotary air lock.

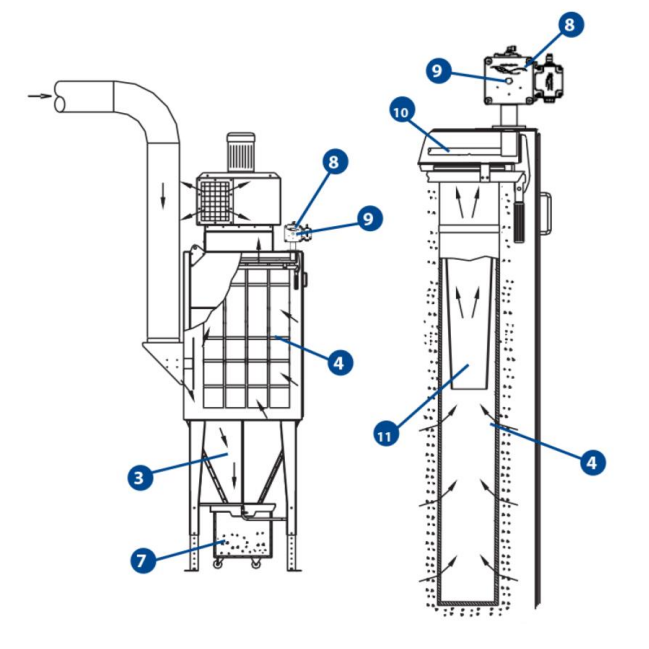

While Cleaning

- The MCP’s IntelliPULSE™ technology controls the compressed air cleaning process by: automatically optimizing the time between pulses, maintaining a constant differential pressure drop across the filters, using the least amount of compressed air as possible.

- You need to connect a compressed air line (9) to one end of the compressed air manifold (8).

- A solenoid value opens to allow compressed air from the compressed air manifold (8) to enter the jet tubes (10). The jet tubes are aligned above each cartridge.

- The UniClean sleeve (11) contains the blast of compressed air from the top to the bottom of each Squircle cartridge.

- The downward blast blows the dust off the filter cartridge (4) where it settles into the into the hopper (3) to then be collected in the metal bin, 55-gallon drum, or discharged through a rotary air lock.

If you’d like a more information on the Nederman line of dusts collectors and related parts, please reach out to us on our Contact Us page by simply clicking here.