If you’re new to the world precision hand files you’ve probably come across a few terms that are a bit perplexing. With this short blog we hope to provide some much-needed clarity.

Common Terms

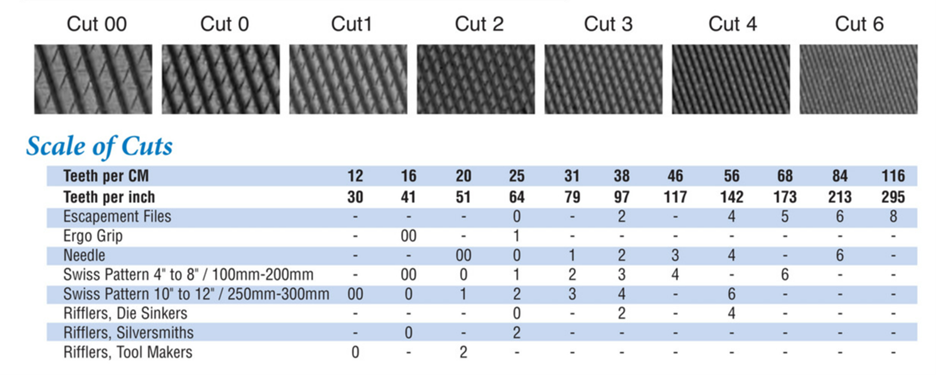

Cut refers to the number of teeth per inch as well as the degree of coarseness of the file’s teeth. Cuts in Swiss precision files range from 00 to 8.

Cut is also used to describe the type of file: single cut or double cut.

The image below helps explain what differentiates the different cuts. A Cut 00 4” Swiss Pattern file, for example, has 41 teeth per inch, while the 10” version has 30.

Double Cut vs. Single Cut – in a Single Cut the teeth are formed on the file by a single series of cuts. With a Double Cut files the teeth are formed by two (2) series of cuts.

Common File Types

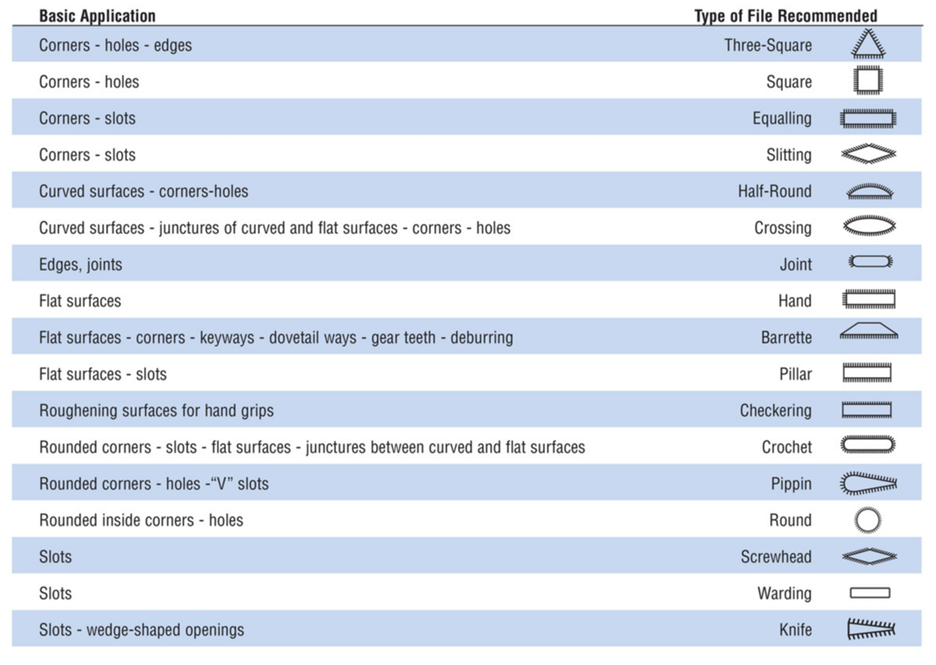

Barrette File – tapered in width & thickness. Cuts on wide flat face.

Checkering File – rectangular in cross section and parallel in width & thickness. Teeth are cut at a 90⁰ angle with the edge.

Crochet File – rectangular in cross section and with rounded edges. Crochet files are cut on both faces and edges. They are also tapered in length and slightly tapered in thickness.

Crossing File – oval cross section and with the same radius as half-round files on one side, with the other side curved to a larger radius. Crossing files are cut on both sides and tapered in width and thickness.

Die Makers’ Rifflers – various cross-sectional shapes. The teeth are cut on a small area on each end, leaving large middle portion to be used as a handle.

Equalling File – thin rectangular cross section, parallel in width and thickness, and cut on both faces and edges.

Escapement Files (also known as Square Handled Files) – a group of files of various cross-sectional shapes with a length of cut varying from ¾” to 2-1/2” and with long square handles. These files are widely used by jewelers, watch makers, and die makers.

Flat File (also know as a Warding File) – a form of escapement or square handled needle file. Parallel in thickness. Cut on four sides and tapered in width.

Handle File – a general purpose file used primarily for working on flat surfaces. Parallel in width and tapered in thickness.

Half Round File – a cross section that is flat on one side and has a radius on the other side. Cut on both sides. Width and thickness taper.

Half Round Slim File (also known as a Ring Files) – same as Half Round except thinner in width.

Knife File – knife shaped, with a cross section that is tapered in width and thickness. The edge has the same thickness from point to shoulder.

Needle File, Round Handled – a group of files of various cross sections with a knurled round handle. The knurling gives the file a positive, no-slip grip for precision filing.

Oval File – an oval cross section tapering in width and thickness.

Pillar File – a rectangular cross section with a thickness greater in relation to width then what is commonly found in other types. Cut on face or flat sides only. Parallel in width, tapered in thickness.

Pipin file – a section that combines the cross section of a round file with that of an equaling file. Tapered in thickness and width.

Round File – round in cross section and tapered in width.

Screw Head File – a narrow diamond shaped section with short bevels to form sharp edges. Cut on beveled edges, safe on flat sides, parallel in width and thickness.

Slitting File – a flat diamond shaped cross section, cut on all sides, and parallel in width and thickness.

Square File – square in cross section, cut on all sides, tapered.

Three Square Files – equilaterally triangular in cross section, cut on all sides, and with sharp corners. This file is tapered.

Warding File – a rectangular cross section with teeth cut on all sides up to 4” in length and on three (3) sides, with one safe edge on files 6” and longer. These files are tapered in width and parallel in thickness.

Please note: all the images used in this post were provided by the Grobet File Company of America. Permission was received for their use prior to the creation of this post.

If you’d like more information, please let us know. You can do so by clicking here to be sent to our Contact Us page.