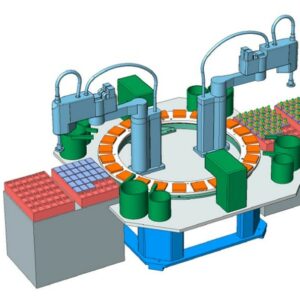

CR Indexers (Heavy-Duty)

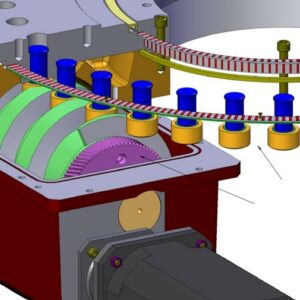

High load & forces

- Constant lead cam (servo driven, freely programmable)

- Great for automotive welding applications

- Larger number of cam-followers are engaged (can carry more inertia)

- Increased inertia

- High Output Torque – always have 5 cam followers engaged in the cam

- Quick index times

- Quick e-stop times (great for light curtain applications)

- Multiple motor options: Weiss control package, Weiss supplied Rockwell motor, customer supplied motor

What We Need to Know in Order to Quote a Rotary Indexing Table

There are a few basic details we need to have in hand to provide a quote. They are:

- Fixed-position or freely programmable?

- Tool plate diameter

- Tool plate thickness

- Tool plate material

- Number of stations

- Number of holes in the tool plate per station

- Weight per station (part + fixture)

- Radius – distance from the centre of the indexer to the centre of gravity for the nests

- Target indexing time

- Dwell time (time in station)

- Motor operation (continuous or cycle-on demand)

- Rotation directions (clockwise, counterclockwise, reciprocating)

- Supply voltage, # of phases, and frequency

- Brief description of the application

- Additional requirements

We’d love to hear from you. Please feel free to send quote requests via our Contact Us page by clicking here.

If you have an application that you require help with and would prefer an in-person consultation that is something we’d be delighted to do as well. Please simply send us a few pertinent details, as well the location of your facility.

We respond to all inquiries made via our website inside of 24 hours.