TR Fixed-Position Rotary Indexing Tables

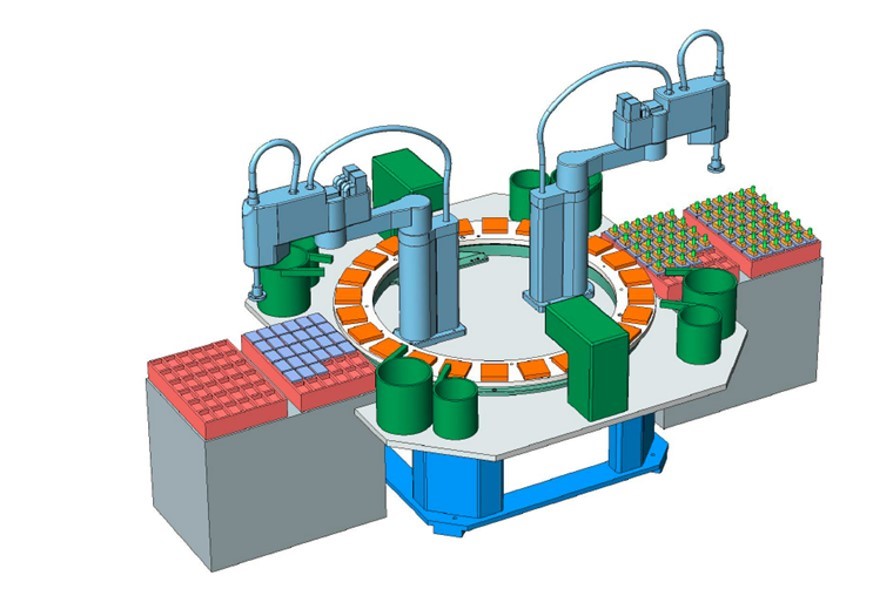

Within the line of Fixed-Station Indexers is the TR line of products. TR indexers provide a sizeable centre hole to permit equipment to be placed at the centre of the indexer. Think of it as building your system from the inside out.

Key features of the TR line if indexers include:

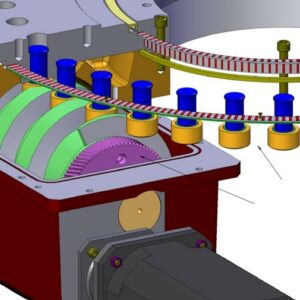

- Same robust design as the TC line of indexers

- Large open centre to permit larger equipment to be mounted at in the centre of the unit

- Same robust design as the line of TC indexers: 4-year mechanical warranty, low maintenance, no overload clutch

- Dial plate comes with a standard mounting pattern to attach a tool plate (2 dowel and 6-8 tapped holes).

- Stationary plate come with 2 dowel holes and 2 to 10 tapped holes.

- Low profile (raised supports available)

- Cam followers run along the entire outside perimeter of the track offering greater levels of accuracy

Controls

- VFD

- Most common option

- Requires the customer PLC to run the indexing logic

- Can adapt supply voltages/frequencies to work with a standard motor

- Eliminates the need for motor brake during normal operation

- Weiss can supply a Rockwell PowerFlex 525 drive, with all parameters set by Weiss North America. Weiss would then include a parameter sheet with the settings. Braking resistors are also available if needed.

- TS Control Card

- Simple Interface that handles the indexing logic

- Requires either motor contactor or VFD for motor power

- Requires an index start input (from the customer’s PLC, safety interlock switch, etc.)

Fixed-Station Rotary Indexing Tables come with a fixed number of stop positions. Once the equipment has been manufactured the number of stops cannot be altered. If you’d prefer the ability to change the number of stop positions later, you’d be better served selecting Freely Programmable Indexers (NC, NR, CR).